Today, the protective industrial coating on a surface is one of the most important methods of keeping a substrate well-protected. That’s why we provide various offshore painting services involving surface preparation and offshore coating for marine paint protection. We understand the importance of keeping a surface clean post preparation and pre-coating application, which is why we provide a range of ICATS and Train the Painter industrial coating applicator solutions to suit your most challenging corrosion protection needs and what makes us today, one of the leading marine coating companies in Northern Ireland.

By using strict paint application, coating quality control and quality assurance processes, we make sure that you are left with a painting job that is well protected from corrosion and resistant to unsafe structural decay. The coating process that we use are built around first hand experiences in industrial trade paint solutions being used on steel surfaces by blaster sprayers today. We look to use industrial paints from paint coating companies such as AkzoNobel, Jotun, Hempel and Belzona amongst other durable specialised industrial coating paint manufactures that form semi permeable barriers against corrosion. With this, you are left with an aesthetically pleasing and integrally sound industrial coatings that does what you would have hoped for, cathodic protection, all offered by one single coating contractor.

Industrial painting provided by our team of coating specialists will often be delivered in a manner that makes a positive immediate impression whether its onshore painting of steel structures in construction or offshore painting of oil rigs and wind farms. That’s why we highly recommend you look to inspect and protect your surfaces with the implementation of an industrial protective coating using a painting contractor like us. After all its what made us an award winning maintenance company and one of the leading marine coatings companies in Belfast.

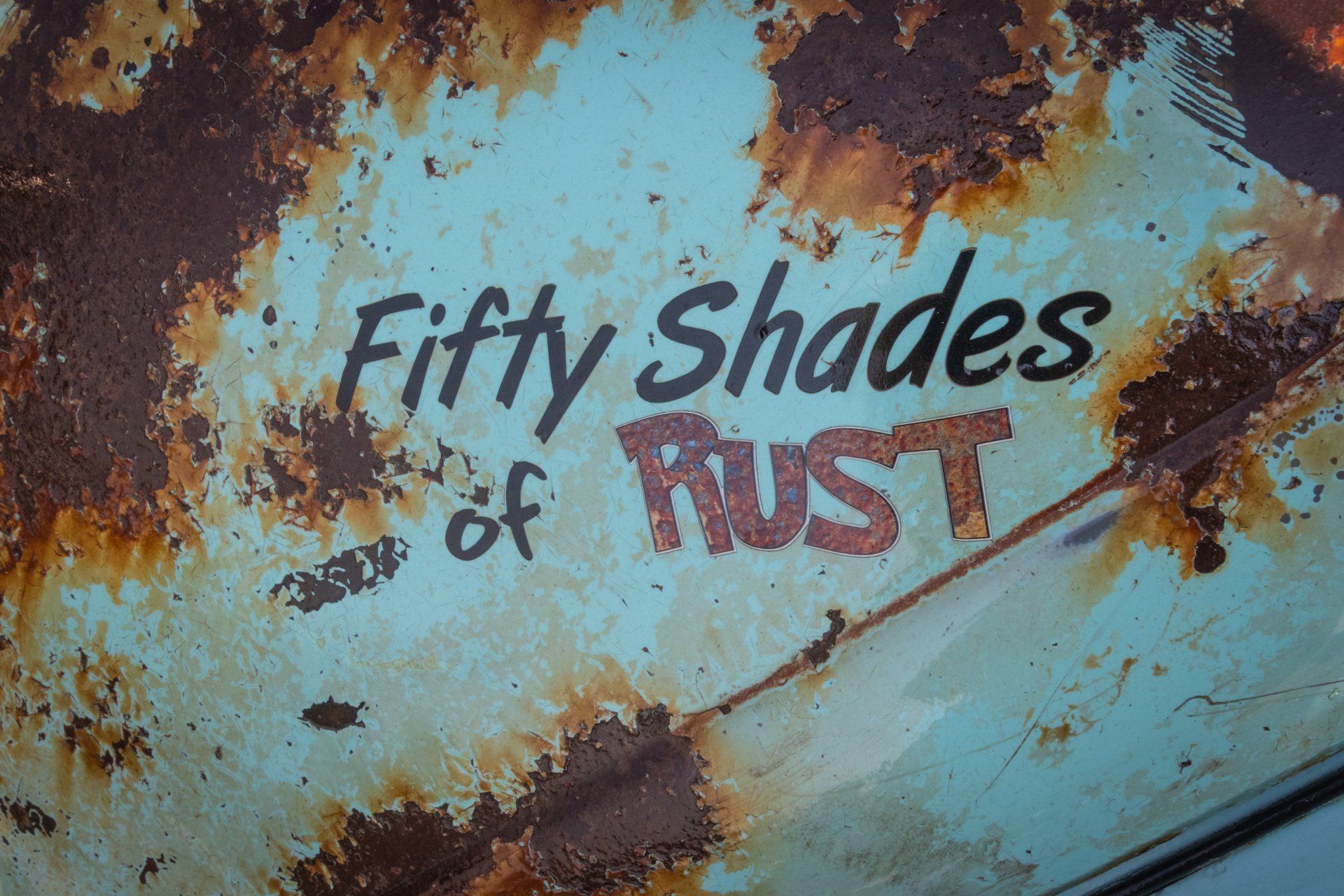

When you want to make sure that a substrate is going to be resistant from wear and tear, you need steel painters to protect it. This means protecting it from physical damage, but also from the environmental impacts of the elements. Regular water landing on the surface can begin to corrode the surface, leaving unsightly rust, known as general corrosion. If that happens, you need to invest in a solution to fix the problem, if you don't it will simply get worse.